Transform your workforce

Engage customers in new ways

Create more resilient supply chains

Build more agile factories

Unlock innovation and deliver new services

Transform your workforce

Transform your workforce

Give your people the tools they need to help business groups move from data to decisions in hours, not months. Equip them to analyze production, sales, and revenue data securely—by utilizing industry standard data security and access controls—while staying connected wherever they are.

Engage customers in new ways

Engage customers in new ways

Know your customers better. See their purchasing patterns, then provide personalized service with powerful insights from your marketing, sales, and service data. Use advanced analysis and AI to remotely monitor equipment and provide proactive, preventative maintenance.

Create more resilient supply chains

Create more resilient supply chains

Discover actionable insights based on warehouse capacity usage, inventory levels, and delivery logistics to uncover bottlenecks in the supply chain. Improved visibility means you’re better positioned to plan for, and meet, future customer demand.

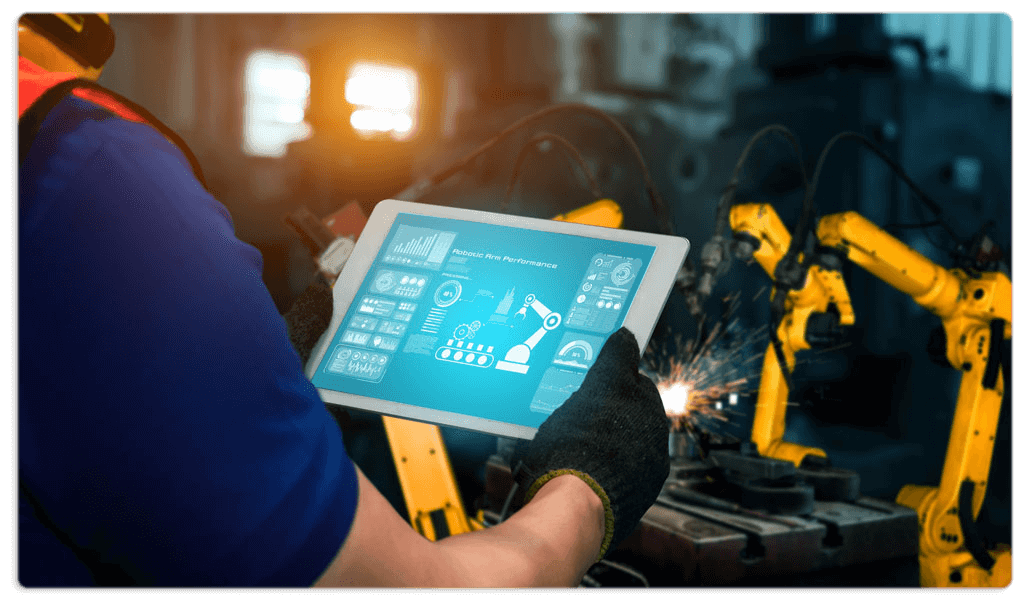

Build more agile factories

Build more agile factories

Quickly identify areas of operational efficiency in real time by analyzing costs, capacity, and output data to avoid delays across the manufacturing line. Visualize terabytes of data from equipment sensors, then use AI to predict hardware issues and prevent production disruptions.

Unlock innovation and deliver new services

Unlock innovation and deliver new services

Create new business opportunities by building a data culture—empowering every employee to access, collaborate on, and analyze data across your organization using self-service data connectors and custom visualization tools.